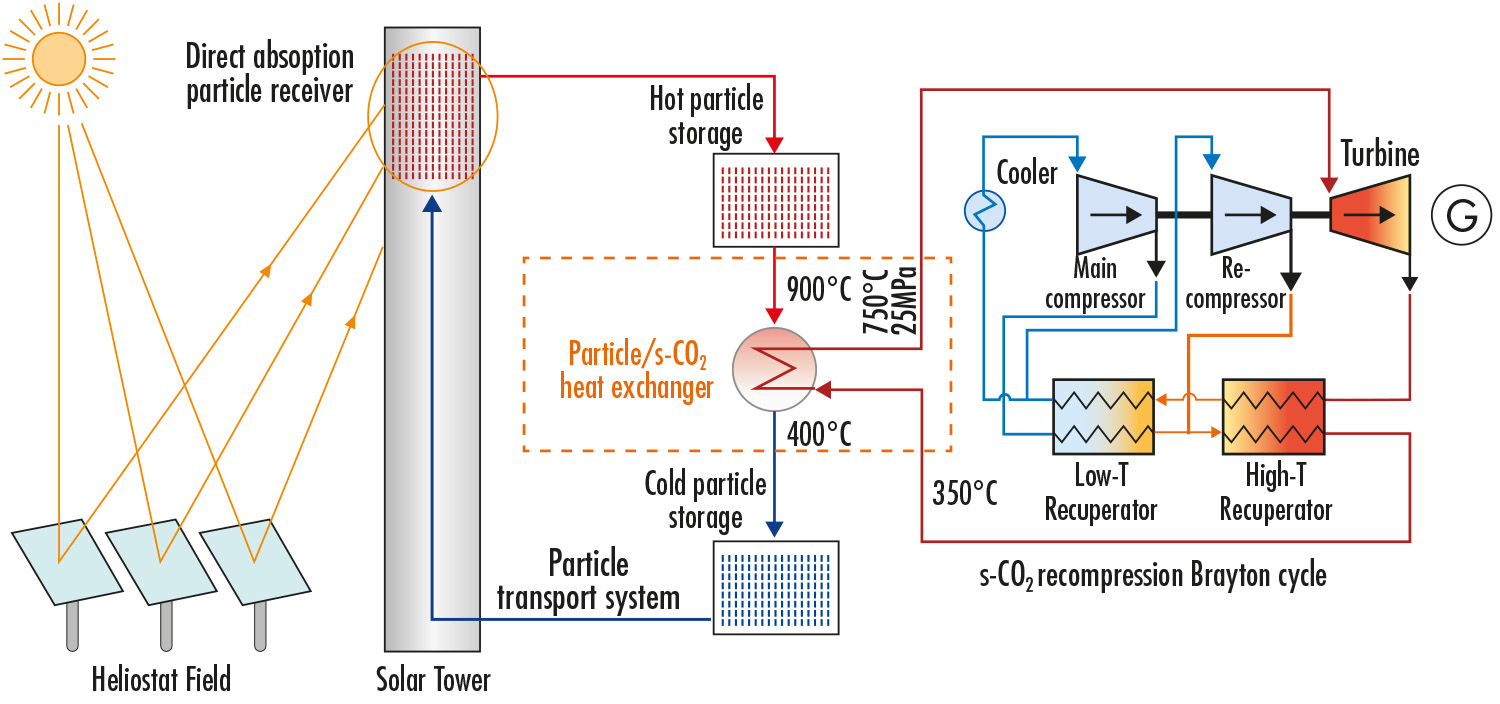

COMPASsCO2 aims to integrate CSP particle systems into highly efficient s-CO2 Brayton power cycles for electricity production. In COMPASsCO2, the key component for such an integration, i.e. the particle/s-CO2 heat exchanger, will be validated in a relevant environment. To reach this goal, the consortium will produce tailored particle and alloy combinations that meet the extreme operating conditions in terms of temperature, pressure, abrasion and hot oxidation/carburization of the heat exchanger tubes and the particles moving around/across them. The proposed innovative CSP s-CO2 Brayton cycle plants will be flexible, highly efficient, economic and 100% carbon neutral large-scale electricity producers.

The research focus of COMPASsCO2 is on three main technological improvements:

- development of new particles

In order for particles to meet high temperatures (over 700°C) new ceramic particles with improved performance will be developed and tested in several volume quantities - development of new metal alloys

This project will provide answers about how the processing and combination with substrate steels will affect the microstructure, phase composition and also chemical stability of the newly developed materials. In addition, measures are undertaken to further develop the chemical composition of the material in order to be able to adjust such materials to the desired properties. The developed materials (monolithic and/or coatings) will be investigated in regard to their behaviour and performance at high temperatures under the CSP conditions. The work aims at modelling the degradation progress with time in long term perspective, and to estimate the lifetimes of the new materials and coatings under different conditions. - development of the heat exchanger section

To validate the interaction between the developed particles and the new structural materials in a relevant environment , the proposal includes the design, construction and testing of a heat exchanger section. Parameters relevant for the lifetime, like attrition rates, and performance parameters, like heat transfer, on the tube and first operating experiences are generated in a relevant heat exchanger environment.

Activities can be summarized as follows:

- To investigate, design, develop and test highly durable and efficient particles for CSP receivers that withstand the conditions for an indirect integration with s-CO2 Brayton cycle.

- To investigate, design, develop and test metal alloys and coatings that guarantee a reliable and efficient operation of the particle/s-CO2 heat exchanger.

- To model the degradation of the materials developed.

- To design, engineer and construct a heat exchanger section to validate the applicability of the components under the harsh conditions of a CSP s-CO2 power plant.

- To assess of the economic competitiveness of a CSP s-CO2 Brayton power plant using the materials and components developed in COMPASsCO2.

- To disseminate the project outcomes to scientific and industrial international stakeholders.