Second Stakeholders Workshop

Two scientific workshops are planned to communicate and disseminate the project's results, facilitate stakeholders' engagement and integration by providing input to the project and widen project outreach and impact.

Workshop Overview

As recalled by the Green Deal Industrial Plan of the European Commission [1], the next decade will be crucial to put the EU on the right track to reach 2050 carbon neutrality objectives. New markets will have been created, breakthrough clean technologies will have been innovated, developed, and brought to market, and our energy systems transformed. Research, development and innovation are key to enable a reliable emission pathway towards sustainable industry, as recalled also in the SPIRE [2] Roadmap. The Horizon 2020 COMPASsCO2 project intends to contribute to sustainability by focusing on a series of key innovations in terms of renewable energy system integration, material durability and process improvement, in line with the SPIRE action concepts. In order to exchange knowledge, validate results and identify areas for improvement, a series of stakeholders workshops are envisaged throughout the project implementation (2020-2024).

This second stakeholder workshop focuses on the demanding material requirements of the proposed concentrated solar power (CSP) particle/Brayton cycle heat exchanger (HEX). On the interior HEX walls the materials will be exposed to supercritical CO2, while on the exterior wall side the materials will be subjected to oxidation and erosion by the hot falling particles. The main research findings to-date will be presented with discussions on project next steps and industrial perspectives. The workshop is addressed to researchers, EU and international consortia working on similar topics, industry representatives and any other interested stakeholder willing to learn more about advanced heat exchangers for supercritical CO2 cycles and aggressive industrial environments towards sustainable industrial solutions for the energy industry.

The workshop is addressed to researchers, EU and international consortia working on similar topics, industry representatives and any other interested stakeholder willing to learn more about innovation for sustainability in industry

[1] Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions: A Green Deal Industrial Plan for the Net-Zero Age, Brussels, 1.2.2023, COM(2023) 62 final.

[2] Sustainable Process Industry through Resource and Energy Efficiency

Agenda

| Time | Topic | Speaker(s) |

| 11:00 – 11:15 | Welcome Coffee | |

| 11:15 – 11:25 | Welcome, Project Overview (CSP HEX) and Workshop Objectives | Daniel Benitez, DLR |

| 11:25 – 12:15 | Session 1: Advanced materials for abrasive environments (Exterior HEX wall) | Mathias Galetz, DFI |

| 11:25 – 11:40 | External wall investigation results | Florian Lebendig, FZJ |

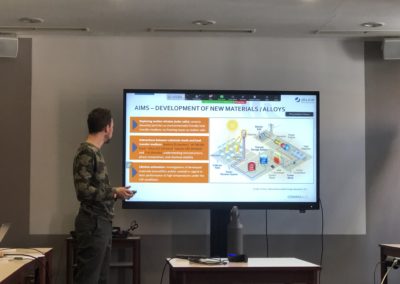

| 11:40 – 11:55 | Development of new materials | Thomas Blackburn, UoB |

| 11:55 – 12:15 |

Roundtable discussion with stakeholders Are there other commercial erosion resistant materials or coatings that should be tested? Costs? Availability? Also applicable as HEX tubes? Is the current testing aggressive enough? Why/why not? Are there other new material directions currently being explored? What is their timeframe? Feasibility of industrial application? |

|

| 12:15 – 13:15 | Networking Lunch | |

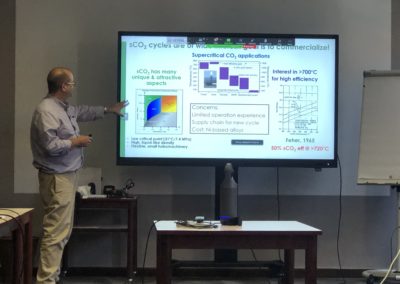

| 13:15 – 13:45 | Keynote Speech: Current status of materials for sCO2 processes for more efficient and sustainable energy systems: approaches and challenges | Bruce Pint, ORNL |

| 13:45 – 14:55 | Session 2: Material behaviour in sCO2 environment (Interior HEX wall) | Mitsutoshi Ueda |

| 13:45 – 14:00 | Materials requirements for sCO2 (oxidation/carburization) | Dmitry Naumenko, FZJ/CIEMAT |

| 14:00 – 14:15 | Testing results on state-of-the-art materials (mechanical properties - creep) | Christoph Grimme, DFI |

| 14:15 – 14:30 | Exploitation opportunities: an industrial perspective | Company participants |

| 14:30 – 14:55 |

Roundtable discussion with stakeholders What properties need to be tested for s-CO2 applications? What experiments should be done? In labs vs. industry? What testing standards exist/should be developed? Are today’s commercial materials applicable in s-CO2? Why/why not? Are there other commercial s-CO2 resistant materials that should be tested? Costs? Availability? Also applicable as HEX tubes? Is oxidation/carburization or erosion more critical? Are there better ways to evaluate these combined properties? Is s-CO2 as far as it will be, as currently defined, or will it go further/be more aggressive in future processes? |

|

| 14:55 – 15:00 | Concluding Remarks & Takeaways | Daniel Benitez, DLR |

| 15:00 | End of meeting |

Presentations

******************************************************

Webinar - sCO2 R&D Activities in Europe

In collaboration with other EU H2020 or nationally funded projects such as CARBOSOLA* (German national project), CO2OLHEAT (coordinated by ETN), DESOLINATION, iSOP, SCARABEUS, sCO2-Efekt (Czech national project), sCO2-4-NPP, and SOLARSCO2OL, COMPASsCO2 took part in a new webinar series on “R&D activities on sCO2 in different applications in Europe.”

The webinar took place on June 12th, 2023 from 14:00 to 15:30 CEST.

COMPASsCO2 presentation is led Maxime Rouzès from John Cockerill Renewables.

The webinar focused on components challenges – heat exchangers: primary heaters.

******************************************************

Webinar - Novel high performance materials and components

Within the framework of joint communication and dissemination activities, in collaboration with other consortia, COMPASsCO2 is taking part in a webinar on “Novel high performance materials and components.”

November 15th, 2022 from 10h00 to 12h00 (CET).

COMPASsCO2 presentation (Novel Cr-Based alloys strengthened by intermetallics for structural and coating applications at high-temperatures >800°C) is led by UoB and DFI partners.

Participating projects: COMPASsCO2, HIPERMAT, ACHIEF, TOPAM, CEM-WAVE, and FORGE.

******************************************************

Webinar - sCO2 R&D Activities in Europe

In collaboration with other EU H2020 or nationally funded projects such as Carbosola, CO2OLHEAT, DESOLINATION, SCARABEUS, sCO2-Efekt, sCO2-for-NPP and sCO2OL Projects, COMPASsCO2 is taking part in a new webinar series on “R&D activities on sCO2 in different applications in Europe.”

The webinar took place on September 22nd, 2022 from 14:00 to 16:00 CEST.

COMPASsCO2 presentation is led by DLR, the Project Coordinator.

The webinar is an introductory event during which each project presented its own objectives & expected impacts, scope, main results/outcomes, and options for further exploitation.

******************************************************

First Stakeholders Workshop

Two scientific workshops are planned to communicate and disseminate the project’s results, facilitate stakeholders’ engagement and integration by providing input to the project and widen project outreach and impact.

Workshop Overview

With the European Green Deal, the EU has set the objective to become a carbon neutral economy by 2050. To reach this ambitious goal, all economic sectors need to engage in a swift transition towards net zero carbon emissions. Research, development and innovation are key to enable a reliable emission pathway towards sustainable industry, as recalled also in the SPIRE[1] Roadmap. The Horizon 2020 COMPASsCO2 project intends to contribute to sustainability by focusing on a series of key innovations in terms of renewable energy system integration, material durability and process improvement, in line with the SPIRE action concepts. In order to exchange knowledge, validate results and identify areas for collaboration, a series of stakeholders workshops are envisaged throughout the project implementation (2020-2024).

The first stakeholder workshop has the purpose to introduce the project, discuss the main research activities conducted, and identify areas in which to cooperate with other projects, institutions or companies.

The main focus areas for this workshop are:

- the use of concentrating solar technology and its integration in the Brayton cycle;

- evaluation of state-of-the-art materials that could withstand the extreme operating conditions and

- research, development and testing of innovative materials that guarantee reliability and sustainability under harsh conditions.

The workshop is addressed to researchers, EU and international consortia working on similar topics, industry representatives and any other interested stakeholder willing to learn more about innovation for sustainability in industry.

[1] Sustainable Process Industry through Resource and Energy Efficiency.

Agenda

| Welcome, Project Overview and Objectives | Daniel Benitez, DLR |

| Investigated system: Description of solar plant combined with Brayton cycle, benefits and limitations | Lukas Heller, DLR Charly Rensonnet, JC |

| Materials for heat exchangers’ tubes: selection, development and evaluation | Xabier Montero, DFI |

| Materials for heat carrier particles: selection, development and evaluation | Samuel Marlin, SGCREE |

Download the detailed agenda here!

Speakers

Daniel Benitez

Scientist at DLR Institute of Solar Research, Systems Qualification Group

Lukas Heller

Scientist at DLR Institute of Solar Research, High Temperature Technologies Department

Charly Rensonnet

Development engineer at Solar and Thermal Storage Department at JC

Xabier Montero

Senior Scientist at the High Temperature Materials Group of Dechema-Forschungsinstitut

Samuel Marlin

R&D Director of the Specialty Grains & Powders Division in the Ceramic Materials Branch of Saint-Gobain (SGCREE)

Presentations

Welcome, Project Overview and Objectives

Investigated system: Description of solar plant combined with Brayton cycle, benefits and limitations

Materials for heat exchangers’ tubes: selection, development and evaluation

Materials for heat carrier particles: selection, development and evaluation